Caran d'Ache: an exemplary environmental company

The Geneva manufacturing company Caran d'Ache has 300 employees working in various activities: chemists, designers, engineers, polishers and mechanics. It is present in 90 countries, and has eleven shops throughout the world, primarily on the Asian and European continents including two in Geneva and one in Zurich. Caran d'Ache is positioned on the Swiss made market and counts environmental performance as central to its business and manufacturing processes. Very early on, the company was wise enough to develop projects aiming at excellence for its Thônex plant in terms of solar energy, recovery of waste heat and energy recovery from manufacturing waste. Faced with the current problems of global warming and scarcity of resources, let’s look at some of the good things that Caran d'Ache has in store.

This article was written in collaboration with Caran d'Ache and especially with Aurélie Perret, responsible for regulatory affairs and HSE, and Noémie Rossier, in charge of communication, to whom Genie.ch is particularly grateful for their professionalism and commitment.

CARAN D'ACHE MAKES ENERGY HIGH-PRIORITY

The development of wood energy as a substitute for fossil fuels

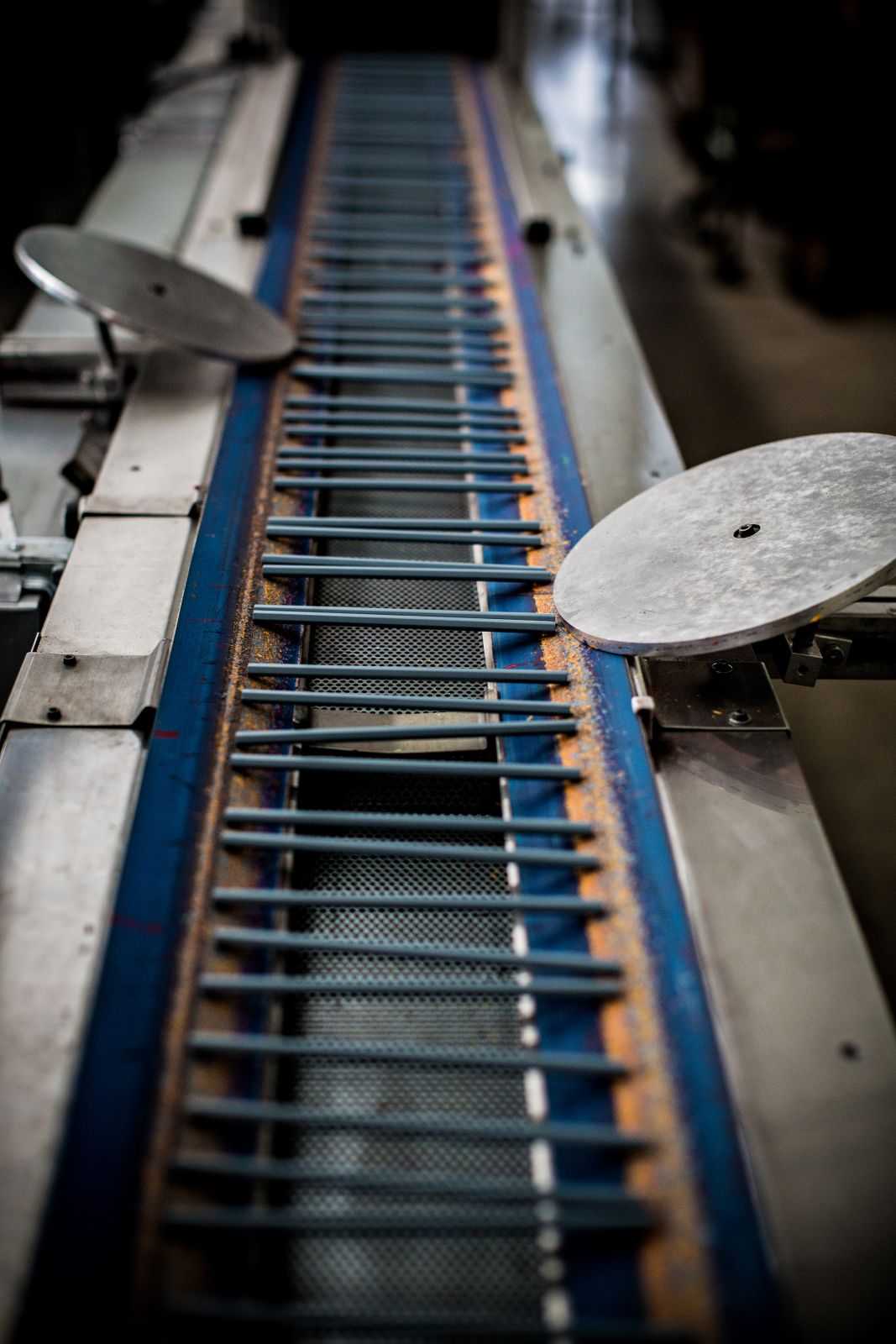

In the 1950s, Caran d'Ache invented and started using a system for recovering wood chips from the manufacture of pencils, in its plants. First at La Terrassière where the company built a chimney and then when designing the plant in Genève in 1974, when management decided to acquire a wood boiler. 80 tons of wood chips from the manufacture of pencils are recovered every year, compacted into briquettes and used to power the central heating in the plant.

Besides being an attractive option financially, the environmental benefits are significant and promising:

- Recovery of co-products

Saving the cost of sending to landfill sites

- Reducing dependence on fossil fuels

This renewable energy produces 388,800 kWh annually. It saves the annual consumption of 38,880 litres of fuel oil, equivalent to 38,418 m3 of gas.

- Combating the greenhouse effect

It reduces CO2 emissions by 102 tonnes compared to oil consumption, and by 72 tonnes compared to gas consumption. This volume of C02 emissions represents 30,098,360 kilometres travelled by car or 75 times around the earth (for reference, the average emission from a car in Europe is 122g CO2 / km. Source: renovation durable.eu).

- Developing renewable energy

Caran d'Ache pencils are made of cedar wood coming exclusively from FSC-certified plantations. FSC-certified wood ensures a neutral carbon balance. This is because the cycle between photosynthesis by trees and using their wood as fuel is in balance and does not lead to additional CO2 emissions. Without replanting, CO2 emission from wood would 0.355kg/kwh.

- Optimizing energy consumption according to season

Since 2007, the new wood boiler has been producing up to 10% of hot water in winter, 25% in spring and autumn and 90% in summer.

All waste from manufacturing and production waste is collected, sorted and recycled

Caran d'Ache recycles cardboard, paper, metals (aluminium, brass, stainless steel, scrap metal), plastic film and wooden pallets, and has been recovering catering waste since 2016.

Nothing is lost: some products deemed not to meet quality criteria are processed to be reintegrated into the production chain. This is so much waste that has not been produced and natural resources saved.

Another initiative of the company concerns water. Caran d'Ache has set up a recycled water circuit with a current capacity of 145 m3 per day. This helps it to reduce its water consumption by 20%, equivalent to potential clean water savings of 30 million litres per year.

Recovery of waste heat

A heat recovery system was fitted to the technical facilities to heat rooms and domestic hot water.

Development of solar energy

In 2010, following a partnership with the Vaud company Romande Energie, the factory installed 800 m2 of solar panels generating 46,940 kWh per year. This facility lowers CO2 emissions by 23 tons each year. After auditing the facilities, the solar system was awarded Naturemade star certification, which ensures compliance with the ecological criteria and standards for the production of 100% renewable energy. This label is recognized as the most demanding in terms of respect for the environment at European level.

Replacing solvents with VOC-free products as part of a move to 100% renewable

Caran d'Ache is one of the pioneering companies in the field of alternative solvents. In 2011, it reduced solvent consumption by 50% by means of various measures.

It developed a water-based varnish, which drastically reduces the use of solvents. Their felt pen ink, for example, contains no solvent and is produced with 95% water. In addition, since the start of its activity, the metal components of writing instruments have been degreased without chlorinated solvent within a closed system. Aurélie Perret explains that "this strategy of gradually removing solvents meets with internal, external and legal requirements in terms of health, safety and the environment".

To clean the plastic moulding injection presses, Caran d'Ache uses the dry industrial technique of cryogenics. This method has the advantage of not using water, unlike high-pressure cleaning, avoids the treatment of secondary residues traditionally treated in effluent treatment plants, and rules out the use of solvents.

To conclude, Graphite pencil leads are produced exclusively from 100% natural products, mainly graphite and clay. Coloured leads and chalk are formulated with natural fillers and binders (kaolin, vegetable gums and beeswax).

Next week, in "News of the members”, look out for the account,by the President of Caran d'Ache, Ms. Hubscher, for the Genie.ch network, .

Contacts within Caran d'Ache

Aurélie Perret, responsible for regulatory affairs & HSE

Noémie Rossier, in charge of communication